![[Translate to Englisch:] ZF Friedrichshafen AG - doubleSlash [Translate to Englisch:] ZF Friedrichshafen AG - doubleSlash](/fileadmin/_processed_/e/8/csm_Snippet_Referenzen_ZF-Scrum_Facebook_7e9e27e5b8.jpg)

Predictive Maintenance for Transmission Systems

Extended Service Life of the TraXon Transmission System Through Predictive Maintenance

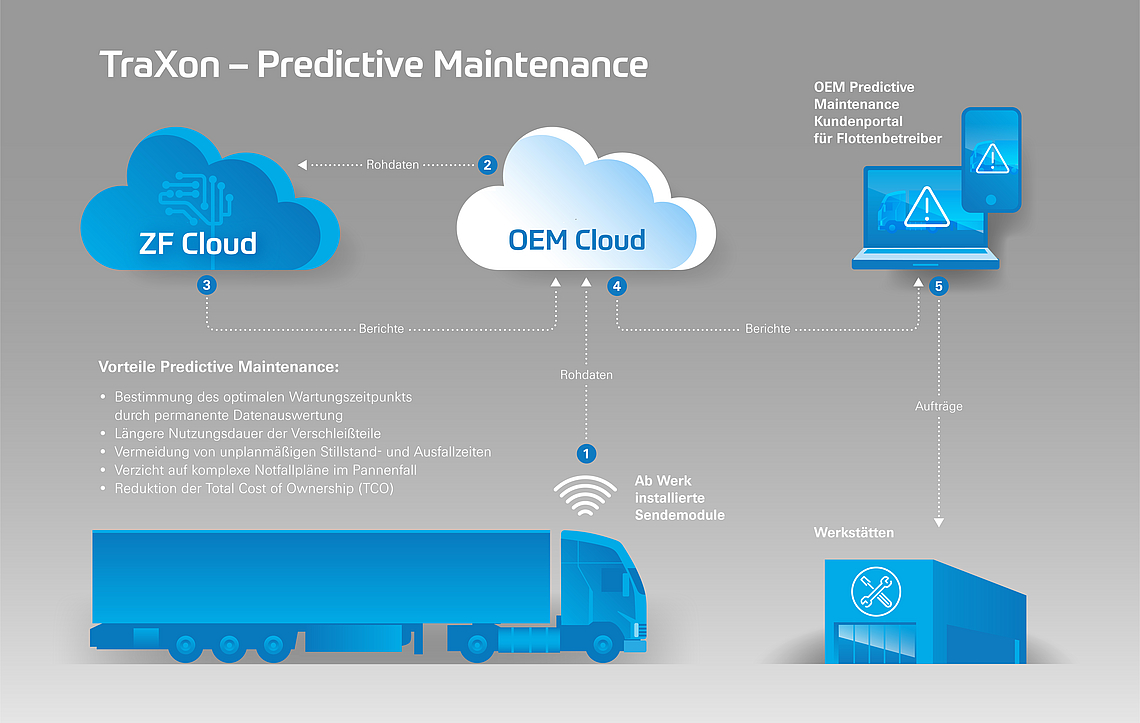

ZF Friedrichshafen AG leverages predictive maintenance to continuously process and visualize data, such as ZF Ecofluid M transmission oil and ZF Sachs clutch performance, from the automated TraXon transmission via the ZF IoT Cloud. By analyzing key transmission KPIs, the goal is to extend the transmission's service life.

Cloud-Based Solutions for Monitoring Transmission Data

ZF Friedrichshafen AG, a global leader in driveline and chassis technology, supplies innovative mobility solutions for passenger cars, commercial vehicles, and industrial technology. The company’s digital transformation has driven the development of new, forward-thinking business ideas. As a strategic partner, doubleSlash supports ZF in implementing future-oriented IoT and cloud computing technologies.

For the ZF TraXon transmission system, forecasts, analyses, and reporting of transmission data are conducted via technical and cloud-based connections. Equipped with a transmitter device, the TraXon transmission continuously sends data to the ZF IoT Cloud, where it is transformed, stored, and processed. Key performance indicators (KPIs) are visualized and analyzed through an intuitive dashboard.

By connecting the transmission to the ZF IoT cloud, ZF is able to read and analyse the transmission data even before maintenance. The backend developed by doubleSlash presents the transmission data automatically, quickly and reliably in the frontend, ensuring optimal analysis results.

Predictive Maintenance: Extending Service Life and Preventing Failures

With predictive maintenance, data from the ZF TraXon transmission can be accessed not only during maintenance but also during regular operation. Using cloud-based technologies, transmission KPIs are transformed, processed, and analyzed. Service life predictions enable longer use of wear parts, while an integrated Analytics API forecasts the lifespan of transmission oil and the clutch. Additionally, standstills and downtimes are identified early, allowing for optimal maintenance scheduling and minimizing disruptions.

Industry Expertise and Years of IoT Experience for Innovative Predictive Maintenance Solutions

As an agile software partner, doubleSlash provided ZF Friedrichshafen AG with comprehensive consulting throughout the project.

We supported the preparation of TraXon for intelligent networking with other vehicle systems, covering all aspects from design and project management to backend development, data visualization, and frontend development. An iterative product development approach was achieved using Scrum methodology.

Our Services

- Agile Project Management

- IoT Architecture

- Agile Software Development

- IoT Backend Development

- Frontend Development

- Data Visualisation

- Design and Functionality

- Testing

- Analytics Evaluations

Technologies Used

- Azure (Key Vault, Azure AD, Event Grid, Application Insights, Function App, Cosmos DB, Logic App, Redis Cache, Blob Storage)

Python

C#

- GraphQL

Power BI

How Can We Assist You?