![[Translate to Englisch:] ZF Friedrichshafen AG - doubleSlash [Translate to Englisch:] ZF Friedrichshafen AG - doubleSlash](/fileadmin/_processed_/e/8/csm_Snippet_Referenzen_ZF-Scrum_Facebook_7e9e27e5b8.jpg)

Predictive Maintenance Solutions for Wind Turbines

Extended gearbox service life and optimum machine utilization

ZF Friedrichshafen AG is a global leader in driveline and chassis technology, as well as active and passive safety systems. Through its integrated solutions, the ZF Aftermarket division ensures optimal performance and efficiency of vehicles and machines throughout their entire lifecycle.

As a component manufacturer in the wind turbine gearbox sector, the company has been working on predictive maintenance since 2016. The turbines are usually distributed around the world and are difficult to access due to their height. Damage investigations, maintenance and breakdowns are therefore time-consuming and costly. This is why a system was developed to monitor plant utilization. It serves to detect failures at an early stage and offers the possibility of identifying optimization potential for plant operation.

Predictive Maintenance for Smart Wind Turbine Gearboxes

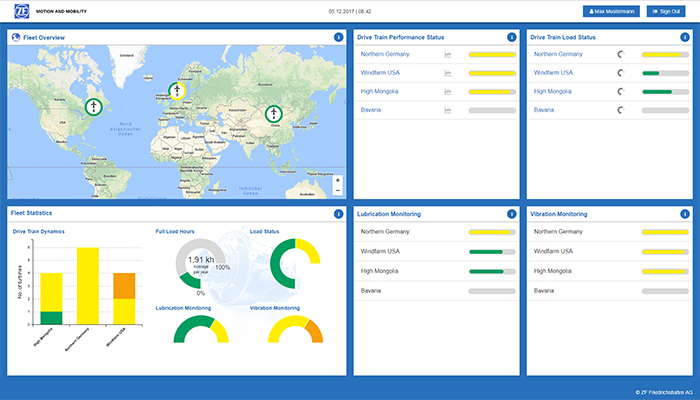

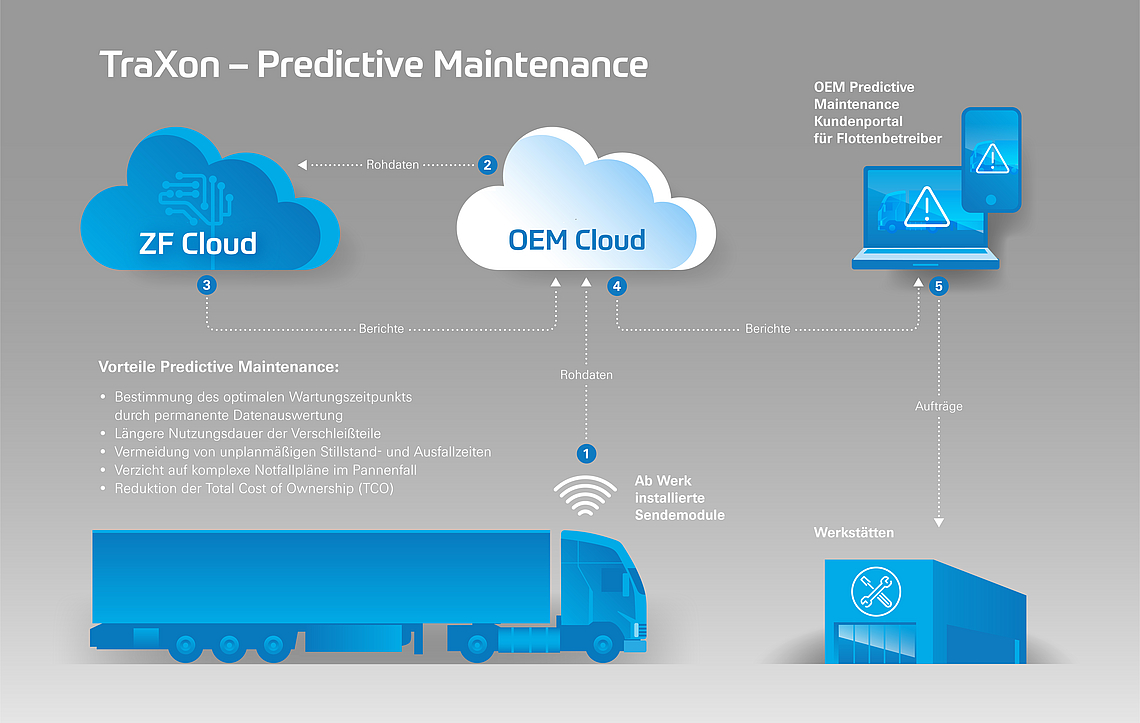

Connecting wind turbines to a cloud-based platform generates significant added value by enabling data-driven insights into gearbox behavior. This data allows for predictions about potential damage, identifying in advance which parts need repair or replacement.

Additionally, operational behavior analysis facilitates predictive interventions, extending gearbox service life and optimizing wind farm management. In this way, ZF takes a pioneering role in predictive maintenance for wind turbines.

ZF’s cloud-based predictive maintenance solution is used to visualise loads and optimisation potential during operation of wind turbines, including detailed calculations for wind turbine gearboxes. It also serves as a platform for cloud-based collaboration with other partners in the field of condition monitoring for wind turbines. The backend developed by doubleSlash in the Microsoft Azure cloud processes data in real time, while the frontend formats the data for presentation to the user. – Dr.-Ing. Andreas Vath, Industrial Technology Division, ZF Industrieantriebe Witten GmbH

Data Management and IoT Expertise for Rapidly Deployable Predictive Maintenance Solutions

doubleSlash served as a strategic software partner in the ‘Predictive Maintenance for Wind Turbines’ project, providing expertise in project management, data visualization, and backend development using Microsoft Azure for system networking.

A clear and effective presentation of live data through the Live Data View was a key focus, enabling initial analysis and facilitating the integration of other stakeholders for a seamless customer experience.

The project, implemented using agile Scrum methodology, was supported by doubleSlash from the initial prototype through to the final solution.

Our Services

- Agile project management

- Business and IT conception

- IoT architecture

- Agile software development

- IoT backend development

- Front-end development and data visualization

- Setting up an environment for data analysis

- Optimization of data storage

- Optimization of calculation algorithms

Used Technology

Microsoft Azure (IoTHub, Stream Analytics, Service Bus, Azure AD, SQL, Blob Storage)

Python

Visual Studio Teamservices 2017