AI-Based Fault Detection and Maintenance Planning in Use

Detect Faults before They Occur

When an industrial production plant suffers an unplanned breakdown, the financial damage is usually considerable. However, downtimes can be reduced by up to 50 percent and maintenance costs by up to 40 percent. With the help of artificial intelligence.

Plant and machine malfunctions are a major problem for manufacturing companies. Although they generally occur infrequently, they are often only recognized when it is too late and the system is already inoperable.

The Consequences Are Often Serious

The implementation of condition-based maintenance and cloud-based IoT solutions enables CHP plant operators to optimize maintenance processes, increase plant availability and improve overall performance while ensuring safety and flexibility.

Artificial intelligence can significantly alleviate the problem. With machines that learn independently and recognize if and when they need maintenance. This not only allows their maintenance to be planned in advance and made more efficient. Downtimes can also be significantly reduced.

Simple Principle

Every machine and every system generates physically measurable variables when it is running: Vibrations, pressure, density, heat... These phenomena can be recorded by sensors and compared with other measurement data. If significant changes occur, they are usually an indication that ball bearings or gears, pumps or motors are no longer running smoothly in the true sense of the word and should be serviced or repaired.

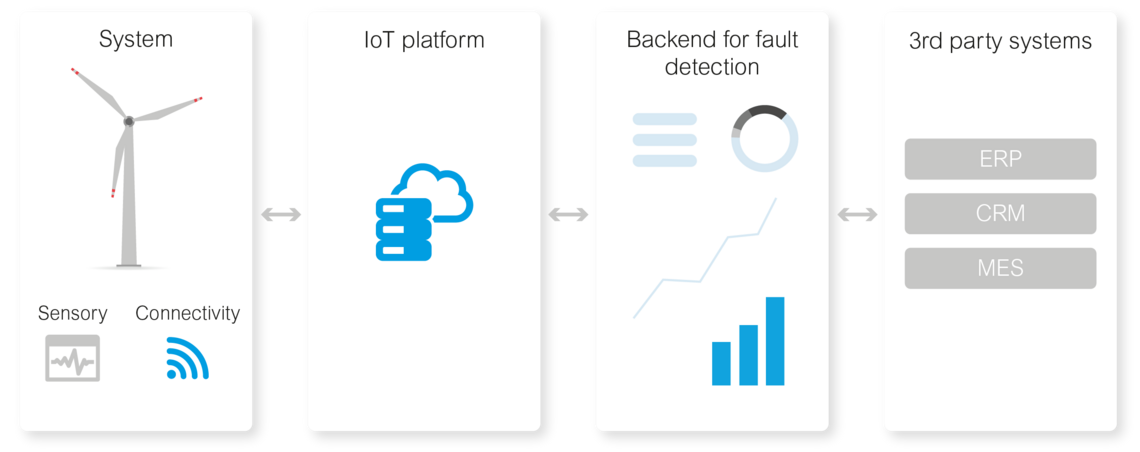

- The system must be equipped with sensors that read out the relevant data.

- It must be able to transmit this data to an IoT platform.

- The platform must be able to handle large volumes of data.

- Suitable data must be available and suitable algorithms must be implemented in order to reliably predict faults.

- Third-party systems such as ERP or manufacturing execution systems (MES) may need to be integrated in order to link the data.

On this basis, intelligent fault detection can be realized using AI methods. However, although the economic potential is huge, many companies are still finding it difficult. There are a few hurdles to overcome first:

The more data is available, the better the algorithms can be trained and the more accurate the results they deliver.

The realization of such projects requires both financial and time investments, as they must be strategically planned and implemented. Specialized experts such as data scientists bring the necessary know-how to successfully implement the project.

Reduce Costs With Software

The use of prefabricated and reusable software components that can be quickly implemented and individually adapted can reduce the effort involved. For this reason, doubleSlash has developed software for intelligent fault detection and maintenance planning for industrial and infrastructure systems, ISII for short.

The idea behind it: Experience, best practices and recurring requirements are poured into standardized software components that can be easily adapted to the respective requirements. Recurring requirements include the versioning of data and models, the deployment and monitoring of models and the selection and use of suitable algorithms. ISII also provides all the functions required for use in customer projects.

Exemplary Procedure for Intelligent Fault Detection With AI

Specific Application Example From Mechanical Engineering

This example shows how ISII can be used to quickly set up a model for predictive maintenance: an international mechanical engineering company has various locations with different machines around the world. These machines transmit vibration data from motors and ball bearings to a cloud-based backend. At the same time, the company wants to regularly launch new motor and ball bearing types on the market.

With ISII, a wizard can be used to quickly create an executable solution for each location and motor or ball bearing type that detects potential damage in advance with a high degree of accuracy. The generated models can be individually customized.

The algorithms, data and models used can be versioned, deployed and monitored. They can be accessed at any time to compare or adapt older models, algorithms and data sets.

This gives maintenance managers the opportunity to keep the cost of introducing and operating a predictive maintenance system within manageable limits. And they can quickly put intelligent fault detection to productive use.

Intelligent Fault Detection - The Advantages at a Glance:

- Early detectionof potentialfaults

- Intelligent, predictive maintenance before the system becomes inoperable

- Avoiding long downtimes

- Minimize downtime costs

- Faster productive use

- Access to many proven methods and best practices for fault detection

- Fast customization

- Versioning of models